The Paris Agreement of 2016 commits signatory countries to limit global warming to below 2oC above pre-industrial levels. Reaching this target will require the decarbonisation of electricity and heat generation, both of which are major contributors to global greenhouse gas emissions, contributing to climate change and environmental degradation.

Many mature technologies are available for renewable energy generation – primarily solar photovoltaics, solar thermal and wind – but these technologies face the problem of intermittency – they can only function most optimally when the sun is shining, and the wind is blowing. Whilst their efficiency is ever improving, until storage solutions for excess energy are further developed, these renewables will only be able to fill part of the energy mix.

Yet some renewables are not intermittent. Both hydropower and bioenergy are on-demand energy solutions, though not without their problems. Hydropower dams have a large environmental impact, with big areas of land needing to be flooded for their construction, with an impact on wildlife like salmon and eels, while existing biomass technologies have low efficiency and new value chains are required to ensure the sustainability of the biomass being used.

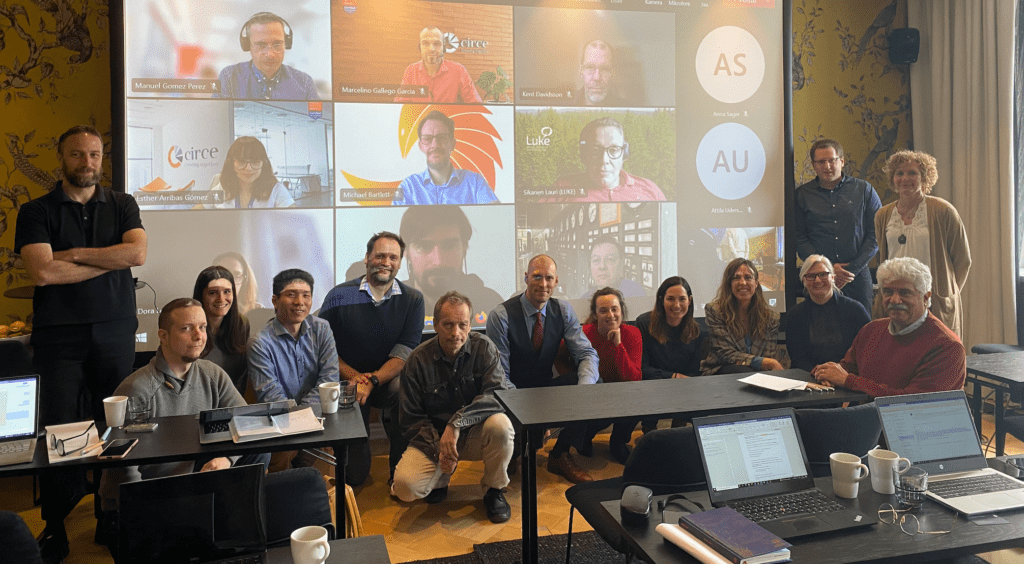

The EUCANWin! project is supported by the European Commission’s Horizon 2020 Framework Programme for Research & Innovation, in the framework of Mission Innovation. It explores the full bioenergy value chain, from sourcing sustainable biomass, to conversion and carbon capture, as well as techno-economic, environmental, and social assessments.

What is the Biomass-Fired Top Cycle?

The Biomass-Fired Top Cycle (BTC) technology, developed by Phoenix BioPower, is a solution capable of meeting the challenge of providing a regular sustainable energy supply. BTC makes use of ‘waste’ biomass resources, such as wood chips, tree branches, straw, bagasse, and corn stover, avoiding harvesting of new trees for energy. In forestry at present, a quarter of biomass is waste that cannot be used for higher-value products but can be used in BTC to produce heat and power with significantly improved efficiency compared to typical biomass-powered steam cycle technologies.

Power production with these traditional technologies, which burn biomass to create steam and drive a generator, can reach just over 30% efficiency, where the BTC can reach up to 55%. As well as efficient electricity generation, heat generated in the process is cycled back and used in the generation process, with excess heat used for district heating systems and/or carbon capture and storage, with low capture costs.

BTC technology has been proven as an experimental proof of concept, marking it at Technology Readiness Level (TRL) 3, with the fundamental concepts tested and characterised in 20-100kW scale rigs. The research actions in EUCANWin! aim to improve the efficiency of the technology and validate the BTC concept in a relevant industrial environment, taking the technology to TRL5. The validated designs, data, knowledge, and models created in the project should significantly help to de-risk upscaling the process steps, and ultimately it is hoped that the technology will achieve a levelized cost of electricity below that of fossil fuel plants.

The benefits of the technology will be multiple. Firstly, it is plannable – as long as there are sufficient biomass resources, BTC plants can be fuelled to provide electricity and heat when needed, around the clock, acting in complement to wind and solar energy. Plants are scalable to different seizes depending on how much energy is needed, and vitally, BTC plants are local and circular, working with local communities for sourcing biomass, providing energy for local use, and addressing disparities between supply and demand in the electricity grid.

BTC Technology has already been recognised for its significant potential, being selected as one of 100 global solutions that could have a climate mitigation potential of more than 10 megatons CO2 equivalent, and therefore of strategic importance for 1.5oC, at the 4th Mission Innovation Ministerial Meeting in Vancouver, in May 2019.

“We are participating in the EUCANWin! project to work with other bioenergy experts and further drive BTC technology development towards commercialisation, with the aim of making it available and commissioned on commercial terms before the end of the decade.”

Henrik Båge, Chief Executive Officer, Phoenix BioPower

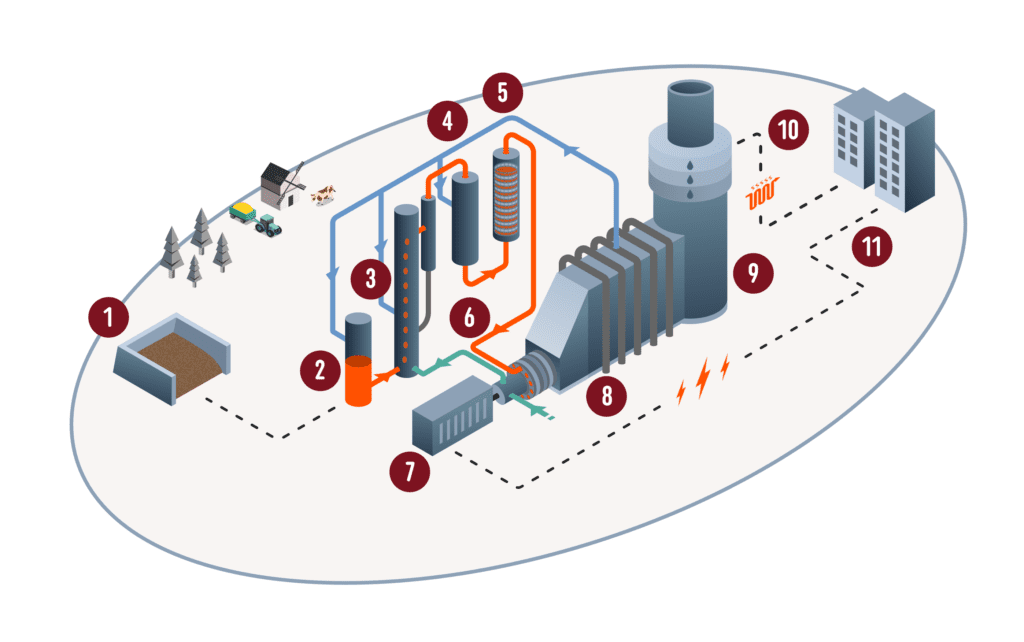

The Process: Step-by-Step

- Biomass – Waste biomass from forestry and agriculture are sourced and brought to the BTC plant. This creates opportunities in the local economy to make use of biomass resources and create new jobs through new value chains and logistics services;

- Feeder – The biomass is pressurised so that it can be fed into the high-pressure gasification reactor;

- Gasifier – The biomass is converted to a gaseous fuel by heating to 800-900oC with steam and compressed air;

- Gas cooler – The gas is cooled to under 500oC, preparing the gas for filtration and clean-up;

- Hot Gas Filter – The gas is cleaned, with contaminants removed using special filter materials;

- Top Cycle Gas Turbine – The clean fuel and steam is combusted with air, creating an ultra-hot gas that drives the turbine;

- Generator – The mechanical power from the turbine is converted into electricity;

- Heat Recovery Steam Generator – Excess heat from the exhaust gases (hotter than 500oC) are recovered by generating steam, which is used circularly for gasification (Step 3) and for cooling (Step 4). The steam is also used in the gas turbine;

- Flue Gas Condenser – Water is recovered from the flue gases and recycled;

- Heat – Excess heat can be used in buildings and industry. Producing heat and power together in one facility reduced fuel consumption by 40% compared to separate production;

- Electricity – Ultimately, up to 55% of the energy embodied in the biomass can be converted into electricity.

For more information on BTC technologies, visit the Phoenix BioPower website, or you can also check out our full interview with Henrik Båge, their Chief Executive Officer.